Shanghai HESON Instrument Technology Co., LTD

沪ICP备10012421号 Power By : www.300.cn

MTG gravel tester

basic information

Brand

HESON

Model

HS-SS-1A

heat

| 1. Product name | |

| Name Model number |

Stone Chip Resistance Gravelometer

|

| 2. Sample description | |

| This test equipment is prohibited: Test and storage of samples of flammable, explosive and volatile substances Testing and storage of corrosive substance samples Testing or storage of biological samples The testing or storage of fluids |

|

| 3. Equipment characteristics | |

|

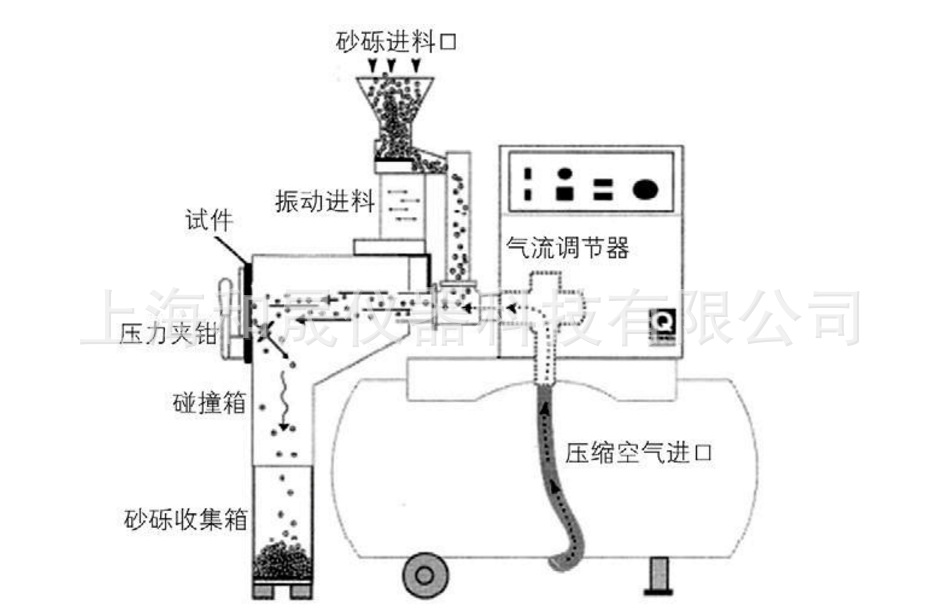

The equipment is composed of: gun assembly, impact box, sample device fixture, feed funnel device (including vibrator), electric control system, air compressor (optional).

|

|

| 4. property | |

| Ambient temperature is 5 ~ 35℃, relative humidity ≤ 85%RH, There are samples in the test chamber Lithotripsy testing of SAE J400 automotive surface coatings ISO 20567-1 - Determination of the resistance of paints and varnishes to stone impact - Part 1: multiple impact tests DIN 55996-1:2001 "Testing of the impact strength of coated materials on crushed stone - Part 1: Multiple impact tests" ASTM D3170-03(2007) GME 60268-96 GMW14700 GM9508P MGR ES30.AD.149 ISO 20567-1-2005 NES M0007 Section 28 DIN EN ISO20567-1-2007 FLTM BI 157-06 This feature specifies the protection capability of the coating to protect the axle from impact damage due to projectiles, such as gravel roadbed. This feature is applicable to category 1. 4.1.4.2 Feature Parameters to be obtained After performing the tests specified in 4.1.4.4, no holes shall be found in the coating, nor shall there be any change from the surface of the test sample. 4.1.4.3 Test sample The test sample shall be an axle or a partial axle covered with a coating for which evaluation is required. 4.1.4.4 Test methods Test samples shall be tested in accordance with Appendix C (Standard version) by firing projectiles at a protected surface. 4.1.5 Resistance to flying sand 4.1.5.1 Overview This feature specifies the protection capacity of the coating to protect the axle from damage due to repeated sand or fly sand impact. 4.1.5.2 Feature Parameters to be obtained After performing the tests specified in 4.1.5.4, the coating surface shall conform to: For Class 1 and Class 2 protection, coating loss rating is 3, For Class 3 protection, the coating loss rating is 4. As described in Appendix D (Standard version). 4.1.5.3 Test sample The test sample shall be an axle or a partial axle covered with a coating for which evaluation is required. 4.1.5.4 Test methods The methodology for assessing the ability to withstand flying sand impact is given in Appendix D (Standard). Appendix C (Standard Version) Methods for evaluating impact resistance of coatings C.1 Principles The test method is to fire the projectile at the protected surface, and then study the change of the coating and the change of the surface of the test sample. C.2 Test sample The test sample shall be a coated axle or a coated protected part of the axle representing the finished part. C.3 Devices The device is a machine that can launch a treated projectile (the diameter of the projectile is :32mm, the top Angle is :105°, and the mass is :60g). It should have a Vickers hardness value of 400. C.4 Programs It is launched by the expansion of a certain volume of compressed air with a pressure of 8 bar to ensure an exit velocity of 19.4m/s. The impact resistance is evaluated at -25°C and ambient temperature. C.5 Presentation of test results After the impact, the surface of the coating should be visually inspected, and once the coating has been removed, the outer surface of the test sample should also be inspected. Surface changes are recorded and compared according to the evaluation criteria given in this standard. |

|

| 4.3. Pressure range | 0~1Mpa |

| 4.4. Flow range | 0~0.08m3/S |

| 4.5. Inside diameter of compressed air pipe | 12.7mm、19mm |

| 4.6. Air tank volume | 136L |

| 4.7. Inside diameter of the gun barrel |

52.6mm\290mm |

| 4.8. Maximum sample size | Width ≦105mm\ thickness ≤ 30mm |

| 4.9. Collision room and 3D collision room | SAE 45°90°,VDA54° 90°,Radiator impact chamber |

| 4.10. noise | ≦130dba |

| 4.11. Mode of operation | Suitable for continuous operation |

| 4.12. Test medium | Grit, sand, steel sand (shot), iron sand (shot) |

| 4.13. Feed rate | Adjustment by electromagnetic vibration feeder |

| 4.14. Airflow pressure, velocity | The built-in storage compressed air pressure and flow rate are kept constant and the speed is controlled by a regulating valve at the nozzle |

Applications

Transaction customer

Selection guide

The next article

Stone Chip Resistance Gravelometer MTG